Lithium Italian Beef Can't Have Italian Beef Lithium

What happens when lithium-ion batteries overheat and explode has been tracked inside and out for the first time by a UCL-led team using sophisticated 3D imaging.

- Video: Understanding how Lithium-ion batteries fail

Understanding how Li-ion batteries fail and potentially cause a dangerous chain reaction of events is important for improving their design to brand them safer to utilize and transport, say the scientists behind the study.

Hundreds of millions of these rechargeable batteries are manufactured and transported each year as they are integral to modern living, powering mobile phones, laptops, cars and planes. Although bombardment failure is rare, earlier this twelvemonth, three airlines announced they will no longer carry majority shipments of lithium-ion batteries in their cargo planes after the US Federal Aviation Assistants tests found overheating batteries could cause major fires.

The report by UCL, ESRF The European Synchrotron, Imperial College London and the National Physical Laboratory, published in Nature Communications today, shows for the first fourth dimension how internal structural damage to batteries evolves in existent-fourth dimension, and provides an indication of how this can spread to neighbouring batteries.

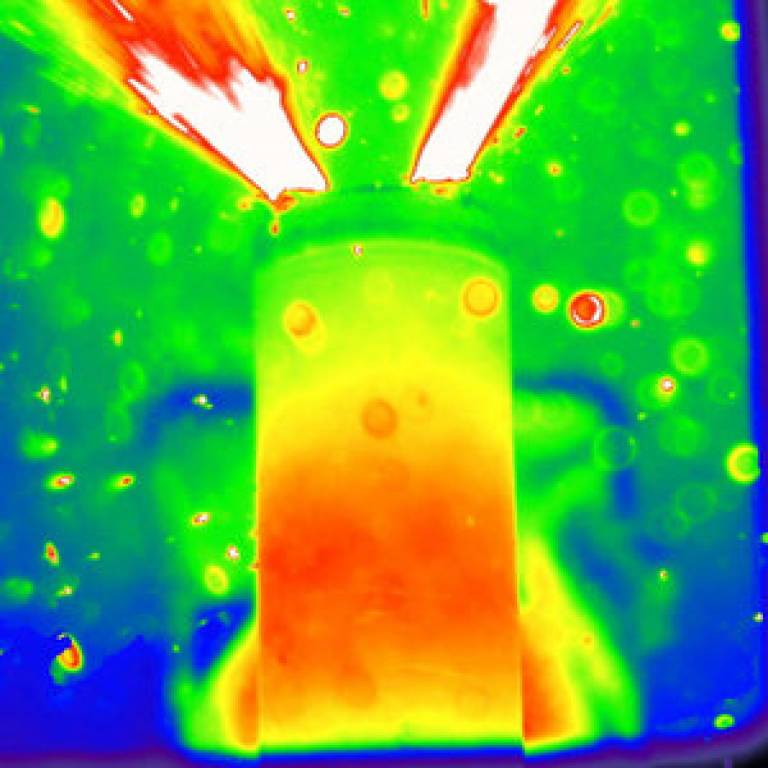

First author, UCL PhD pupil Donal Finegan (UCL Chemical Engineering), said: "We combined high energy synchrotron X-rays and thermal imaging to map changes to the internal structure and external temperature of 2 types of Li-ion batteries as we exposed them to extreme levels of oestrus. Nosotros needed uncommonly high speed imaging to capture 'thermal runaway' - where the battery overheats and tin ignite. This was accomplished at the ESRF beamline ID15A where 3D images can be captured in fractions of a second thanks to the very high photon flux and high speed imaging detector."

We pushed the batteries a long style to make them neglect by exposing them to atmospheric condition well outside the recommended safe operating window. This was crucial for us to ameliorate understand how battery failure initiates and spreads. Hopefully from using our method, the design of prophylactic features of batteries can be evaluated and improved.

Previously, X-ray computed tomography (CT) had but been used to analyse bombardment failure mechanisms mail-mortem with static images and to monitor changes to batteries under normal operating conditions.

The team looked at the effects of gas pockets forming, venting and increasing temperatures on the layers inside ii singled-out commercial Li-ion batteries as they exposed the battery shells to temperatures in excess of 250 degrees C.

The bombardment with an internal support remained largely intact up until the initiation of thermal runaway, at which bespeak the copper textile inside the prison cell melted indicating temperatures upward to ~1000 degrees C. This estrus spread from the inside to the outside of the battery causing thermal runaway.

In contrast, the bombardment without an internal support exploded causing the entire cap of the battery to detach and its contents to squirt. Prior to thermal delinquent, the tightly packed core collapsed, increasing the risk of astringent internal brusk circuits and damage to neighbouring objects.

Corresponding author, Dr Paul Shearing (UCL Chemical Engineering), said: "Although we only studied two commercial batteries, our results show how useful our method is in tracking battery damage in 3D and in real-fourth dimension. The destruction we saw is very unlikely to happen under normal conditions as we pushed the batteries a long style to make them fail past exposing them to conditions well outside the recommended prophylactic operating window. This was crucial for us to better sympathise how battery failure initiates and spreads. Hopefully from using our method, the blueprint of safety features of batteries can be evaluated and improved."

The team now plan to study what happens with a larger sample size of batteries and in particular, they volition investigate what changes at a microscopic level crusade widespread battery failure.

This written report was funded by the Majestic University of Engineering, Engineering and Physical Sciences Research Quango (EPSRC) and National Physical Laboratory. The 'axle time' to conduct these experiments was provided by the ESRF.

Links

- Inquiry paper in Nature Communications

- Dr Paul Shearing's bookish profile on Iris

- UCL Chemical Technology

- UCL Engineering

Image

- Battery showing thermal delinquent during thermal abuse tests (Credit: Donal Finegan, UCL)

Media contact

Bex Caygill

Tel: +44 (0)20 3108 3846

Email: r.caygill [at] ucl.air-conditioning.great britain

Source: https://www.ucl.ac.uk/news/2015/apr/tracking-exploding-lithium-ion-batteries-real-time

Post a Comment for "Lithium Italian Beef Can't Have Italian Beef Lithium"